- New technology

- Improvement in the ACU installation method

Notice: Undefined offset: 3 in /www_root/html/_skin/layout/inc_navigation_middle.php on line 86

Improvement in the ACU installation method

Improvement in the ACU installation method

Efficient space utilization and cost reduction through a change in the construction method Download

Main features

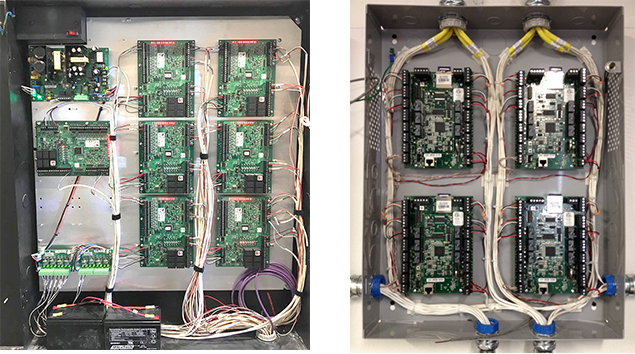

The existing ACU installation method takes up a lot of space in the TPS room as it manufactures the ACU to match the number of card readers in the TPS room and attach them to the wall.

-

- In addition, it takes a lot of time for piping work and cable installation and arrangement, causing great difficulty to lay cables when adding equipment.

<Existing construction method>

-

- - RACK TYPE ACU can be extended to install up to 16 doors.

- - If the equipment fails, the slot type makes it easy to replace it rapidly.

<RACK TYPE>

| Classification | Previous method | How improvements are made |

|---|---|---|

| Construction method | TPS room wall construction | TPS room wall construction |

| Pros | Method of building for delivery to manufacturer without additional cost |

Wall piping/wiring materials and labor costs are reduced Convenient equipment construction reduces labor costs Convenient terminal connection and cable arrangement reduce labor costs Easy to expand additionally and modify Small installation space makes better use of the space of the TPS room |

| Cons |

Difficulty in piping/wiring A lot of time and cost is spent on equipment construction and cable arrangement High cost arises for further expansion and modification |

Equipment costs rise due to change of main control unit (ACU) |